AutoEDU is proud to participate in the SkillsUSA North Carolina Automotive Beginner State Competition. With a commitment to quality automotive teaching equipment, AutoEDU presents real-world OEM-based training tools to prepare students for the demands of today’s automotive industry. At this event, participants are challenged with real diagnostic and assembly tasks using advanced automotive training systems.

Competition Format: Real Tasks, Real Tools, Real Learning

Each student has just 15 minutes per station to complete three hands-on tasks per product. AutoEDU’s trainers are made from real vehicle parts, reflecting true mechanical and electrical systems. This competition format supports practical learning in automotive fault diagnosis training equipment, reinforcing technical skills through real component interaction.

AutoEDU Training Systems in the Competition

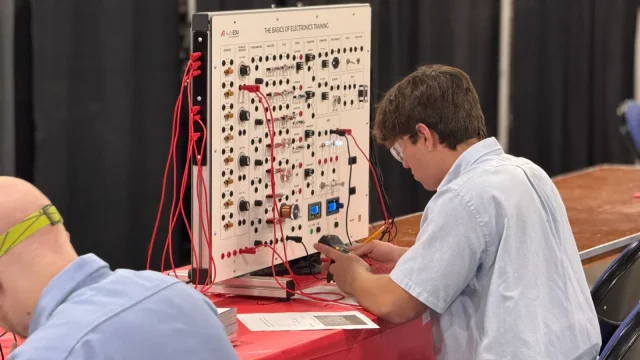

MSEMP01 – Basics of Electronics Training Stand

This compact, safe, and mobile unit introduces students to essential electronics found in all vehicle systems. It includes real components such as resistors, transistors, relays, and LED indicators.

Practical Tasks:

- Decade of Resistors – Students connect a circuit, adjust resistance, measure current, and rate LED brightness levels.

- Pulse Width Modulation (PWM) Control – Learners observe changes in bulb brightness and behavior by adjusting PWM signal parameters.

- Relay Activation – Competitors connect a circuit and analyze the relay’s operation when a push button is pressed.

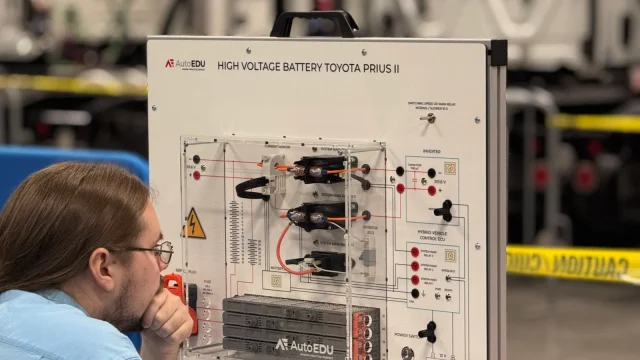

HYBBAT02 – Toyota Prius High Voltage Battery Stand

This hybrid vehicle training system is based on a real Toyota Prius high-voltage battery. It simulates the safety, measurement, and service steps used in high-voltage EV diagnostics.

Practical Tasks:

- Service Plug Removal – Following Toyota’s safety protocols, students safely remove the service plug using protective equipment and observe mandatory wait periods.

- Service Plug Check – They inspect the plug’s electrical contacts and measure resistance to verify fuse integrity.

- Voltage Measurement – Participants measure total battery voltage and module voltages before and after service plug removal.

IVDB03 – Gasoline DOHC Engine Cutaway Educational Trainer

Built from a real Volkswagen Golf V (BAG engine), this engine cutaway model exposes internal structures like camshafts and timing components.

Practical Tasks:

- Auxiliary Drive Belt Installation – Students analyze belt routing diagrams and perform a correct installation.

- Water Pump Replacement – Participants remove and reinstall a water pump, selecting proper torque values from a technical table.

- Timing Chain Alignment – Learners align engine shafts, position crankshaft, and prepare for chain replacement using tools such as dial gauges and locking pins.

Training Equipment Designed for Real-World Use

All AutoEDU vehicle trainers are made from OEM components and delivered in a plug-and-train format – fully functional, classroom-safe, and compact. They allow students and instructors to focus on system operation, diagnostics, and safety procedures without setup complexity.

AutoEDU’s Mission: Building Future Automotive Professionals

As a global automotive training equipment supplier, AutoEDU supports vocational institutions, public tenders, and skill competitions with custom-built trainers, including:

- Engine trainers and gearbox models.

- Manual and automatic transmission cutaways.

- Functional models for electrical, electronic, and mechanical systems.

- Hybrid and electric trainers with high-voltage safety features.

AutoEDU is committed to merging traditional learning with today’s technological demands, preparing students for modern workshops and diagnostic centers.

For more information about our cutaway models, engine trainers, or to learn how AutoEDU can support your educational programs, visit www.autoedu.com.