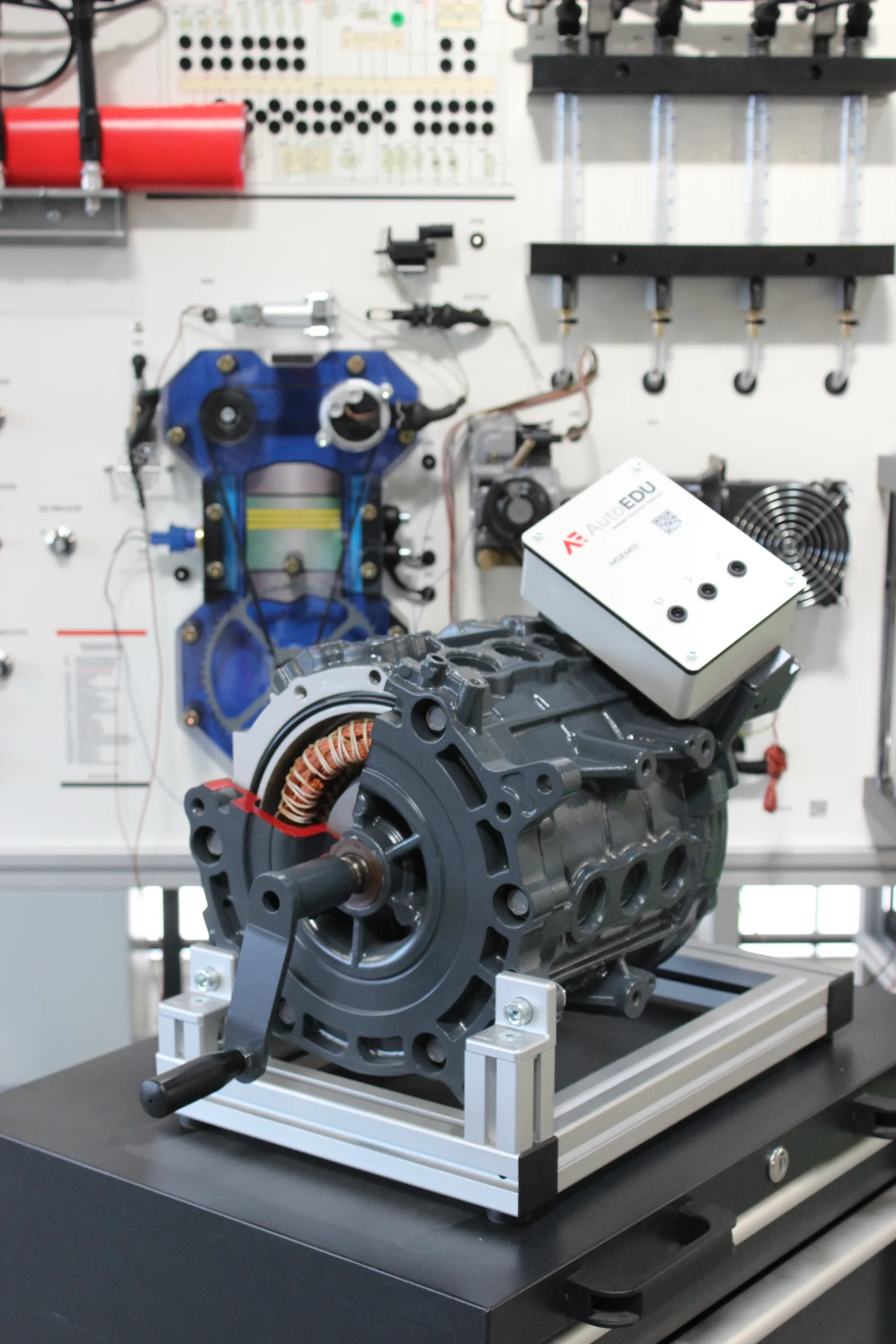

As electric vehicles (EVs) continue to dominate the global automotive industry, the demand for qualified EV service and repair professionals is growing rapidly. To meet this challenge, AutoEDU has developed a new hands-on educational solution – the MSEM01 Electric Motor/Generator Trainer, based on a real Nissan Leaf electric motor. This training tool is designed to help students understand the structure and working principles of EV motors through safe and interactive learning.

Training the Future of EV Maintenance

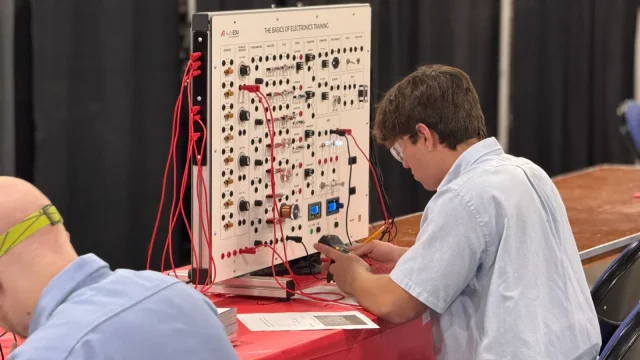

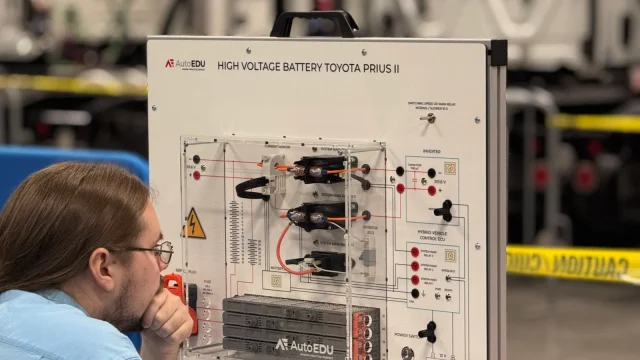

Understanding the internal structure and function of electric motors is critical for future technicians, especially as EV systems differ significantly from traditional combustion engines. However, working directly with high-voltage components can be dangerous without proper preparation.

This trainer eliminates risk by offering a non-powered manual simulation of electric power generation. Trainees can operate the system using a crank handle to rotate the rotor, simulating three-phase energy production in a safe, controlled environment. This method allows for practical experience without exposure to live high-voltage circuits, significantly improving safety during initial training stages.

Interactive and Visual Learning Experience

What makes the MSEM01 unique is its interactive feedback system. As students turn the manual handle, the rotor spins inside the stator, simulating electromagnetic induction. A built-in LED strip responds in real-time, increasing in length and changing color depending on the speed of rotation. This provides immediate visual feedback, helping learners understand the relationship between mechanical effort and electric energy output.

To deepen understanding of real-world scenarios, the trainer also includes fault simulation of a damaged circuit. This feature allows instructors to create controlled faults in the system, helping students learn how to identify and diagnose failures in EV motor circuits safely and accurately.

Key Features of the MSEM01 Trainer

- Real EV motor from Nissan Leaf for realistic structure and operation.

- Manual crank system for safe, hands-on power generation simulation.

- LED power indication strip visualizes energy output.

- Three-phase output terminals (U, V, W) for oscilloscope or multimeter connection.

- Cutaway design reveals internal rotor, stator, and windings.

- High-voltage terminals under transparent safety glass for visible yet protected observation.

- Fault simulation of damaged circuit for troubleshooting and diagnostic practice.

- Robust aluminum frame for classroom durability.

Explore AutoEDU’s EV Training Ecosystem

The MSEM01 joins AutoEDU’s expanding range of electric vehicle training aids, each designed to cover a critical aspect of EV service education:

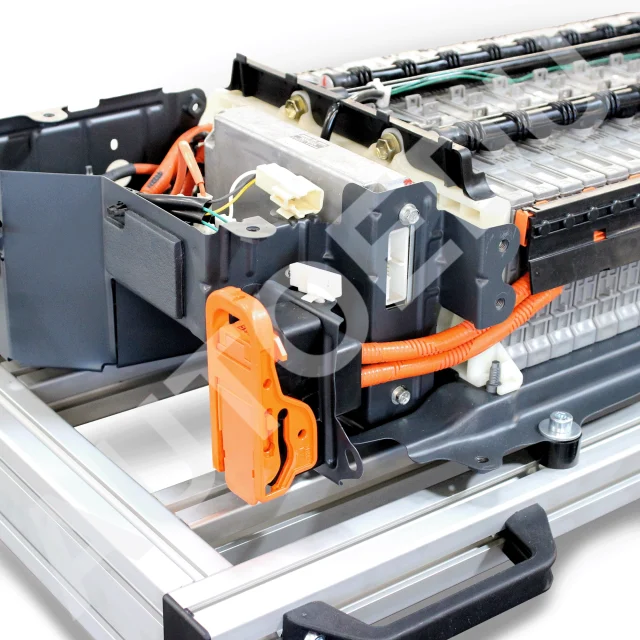

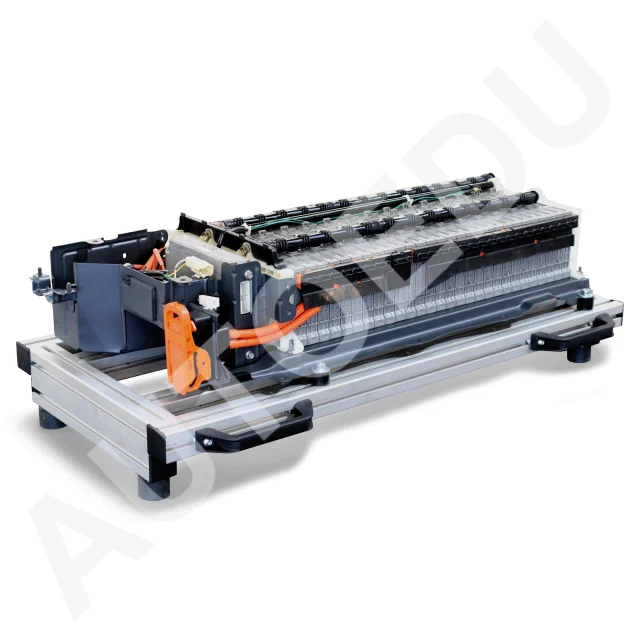

- High Voltage Battery Disassembly and Assembly Trainer – VIVV01 HYBBAT

Learn safe handling, disassembly, and reassembly of high-voltage EV batteries. - Electric Vehicle Training Stand – MSEV02

Full EV drive system on a stand, with integrated diagnostics and control systems. - Functional Educational EV Trainer – AE02

Demonstrates real EV operations with actual components and interactive elements. - Junction Box & Motor Reducer Cutaway – AERZ65

Detailed cutaway for studying high-voltage distribution and motor-reduction systems. - High Voltage Source Disconnection Trainer – MSAE1021

Simulates safe high-voltage disconnection procedures for service technicians.

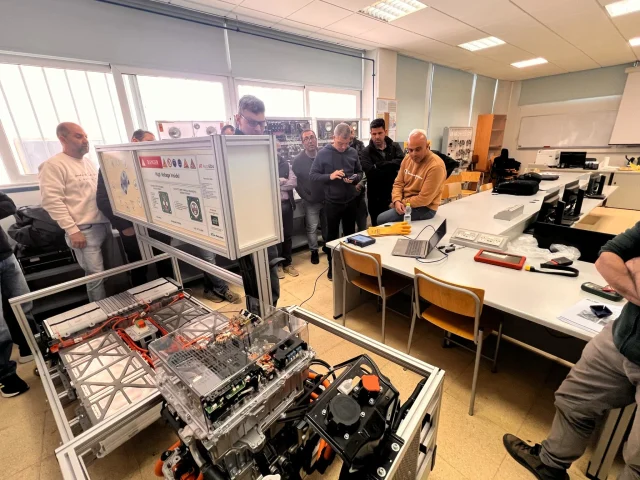

Shaping the EV Workforce Worldwide

At AutoEDU, we are committed to equipping the next generation of technicians with the tools and knowledge needed to succeed in the rapidly evolving automotive industry. Our EV and hybrid training solutions are already used in educational institutions, technical schools, and training centers across Europe, Asia, Africa, and the Americas.

By combining real automotive components, interactive simulations, and safety-focused designs, we prepare students to enter the EV service market with the skills and confidence required by modern repair standards.

The MSEM01 Electric Motor/Generator Trainer is another step forward in building a smarter, safer, and more skilled global workforce for electric mobility.