Cylinder deactivation may sound like a modern innovation, but the concept dates back over 40 years. Today, it’s been reimagined and refined to help car manufacturers meet stricter emissions standards and fuel efficiency goals—without sacrificing engine performance. At AutoEDU, we teach students to not just understand how this system works, but to work with it hands-on and diagnose it confidently.

What Is Cylinder Deactivation?

Cylinder deactivation is a system designed to temporarily shut down a portion of an internal combustion engine’s cylinders under specific conditions. This typically occurs when the vehicle is cruising at a constant speed, under light load, or during deceleration. Instead of firing all cylinders, the engine runs on a reduced number—commonly switching from 8 to 4 cylinders or from 6 to 3.

The system works by cutting off fuel injection and spark to the selected cylinders. Additionally, special mechanisms either collapse valve lifters or lock rocker arms in a way that keeps intake and exhaust valves closed. This allows the inactive pistons to move without drawing in air or pushing out exhaust gases, effectively sealing them off from the combustion process. The air trapped inside these cylinders acts like a spring, compressing and decompressing with each stroke, but not consuming energy in the process. This “air spring” effect reduces internal friction and helps balance the engine.

The vehicle’s powertrain control module (PCM) manages this process using data from multiple sensors. When the engine load increases—for example, during acceleration or hill climbing—the PCM instantly reactivates the deactivated cylinders. The transition is seamless, and the driver typically doesn’t feel the change unless they’re specifically monitoring for it.

How Does It Work?

Although the exact mechanism varies by manufacturer and engine design, the basic principle involves disabling the valvetrain and ignition functions in specific cylinders. In pushrod engines like GM’s V8s, cylinder deactivation is achieved by using oil pressure to collapse special hydraulic valve lifters. When activated, these lifters prevent the pushrods from moving the rocker arms, which means the valves stay closed. Fuel injectors and ignition coils in these cylinders are also turned off by the PCM.

In overhead camshaft engines, such as those from Honda, the system uses oil pressure to unlock rocker arms from their cam lobes. These rocker arms float freely when deactivated, so the valves don’t open. Once full power is needed, oil pressure re-locks the arms, allowing normal valve motion to resume.

Advanced systems like GM’s Dynamic Fuel Management (DFM) go even further. Instead of deactivating a fixed group of cylinders, DFM dynamically chooses which cylinders to shut down based on load conditions. This real-time management allows the engine to operate with any number of active cylinders between two and eight, depending on need, significantly improving fuel efficiency under varying conditions.

The Evolution of an Old Idea

The first mass-produced cylinder deactivation system came from Cadillac in 1981. Their V8-6-4 engine attempted to use early electronics to disable cylinders and improve economy. While the concept was sound, the technology of the time wasn’t sophisticated enough to handle the complex transitions reliably. The result was a system that performed poorly and was quickly phased out.

Fast forward to the mid-2000s, and the computing power and sensor technology had caught up. Chrysler introduced its Multi-Displacement System (MDS) in 2005, applied to their 5.7L Hemi V8. Around the same time, General Motors released Active Fuel Management (AFM) for their LS-based V8 engines. Honda launched its Variable Cylinder Management (VCM) system for V6 engines, mainly targeting fuel savings in minivans and sedans.

By 2013, Volkswagen brought cylinder deactivation to small-displacement engines, applying it to a 1.4L TSI inline-four using their Active Cylinder Technology (ACT) system. This was a key milestone, proving that even small turbocharged engines could benefit from shutting down unused cylinders under low-load driving.

Real-World Performance and Benefits

The primary reason automakers use cylinder deactivation is improved fuel economy. Under light load, the engine doesn’t need all cylinders to maintain speed or cruise efficiently. By reducing the number of firing cylinders, less fuel is injected, and emissions are reduced. On highways, this can translate into a 5–15% improvement in fuel consumption, depending on vehicle weight, engine size, and driving style.

In addition to saving fuel, cylinder deactivation also helps reduce tailpipe emissions. With fewer cylinders running, less carbon dioxide (CO₂) and nitrogen oxides (NOₓ) are produced. In tightly regulated markets, this makes a big difference in helping vehicles meet environmental standards without switching to more complex hybrid systems.

An often-overlooked benefit is reduced engine wear. Deactivating cylinders lowers internal heat and friction in those parts of the engine, which can extend component life and improve long-term reliability—especially in well-maintained engines.

Common Applications Today

Cylinder deactivation is now common across multiple brands and vehicle types. GM’s 5.3L and 6.2L V8s use either AFM or DFM, depending on the model year and platform. These systems are widely used in pickup trucks, SUVs, and some high-performance sedans.

Chrysler’s MDS is standard on many 5.7L Hemi engines found in Dodge Chargers, Jeep Grand Cherokees, and Ram trucks. Honda’s VCM system continues to power vehicles like the Odyssey, Pilot, and Ridgeline.

Some smaller engines now feature one or two-cylinder deactivation modes—like Ford’s EcoBoost 3-cylinder engines, which can shut down a cylinder under light load. European manufacturers like Volkswagen and Audi have also integrated cylinder deactivation into compact turbocharged engines, helping meet European CO₂ targets.

Technician Insights from the Workshop

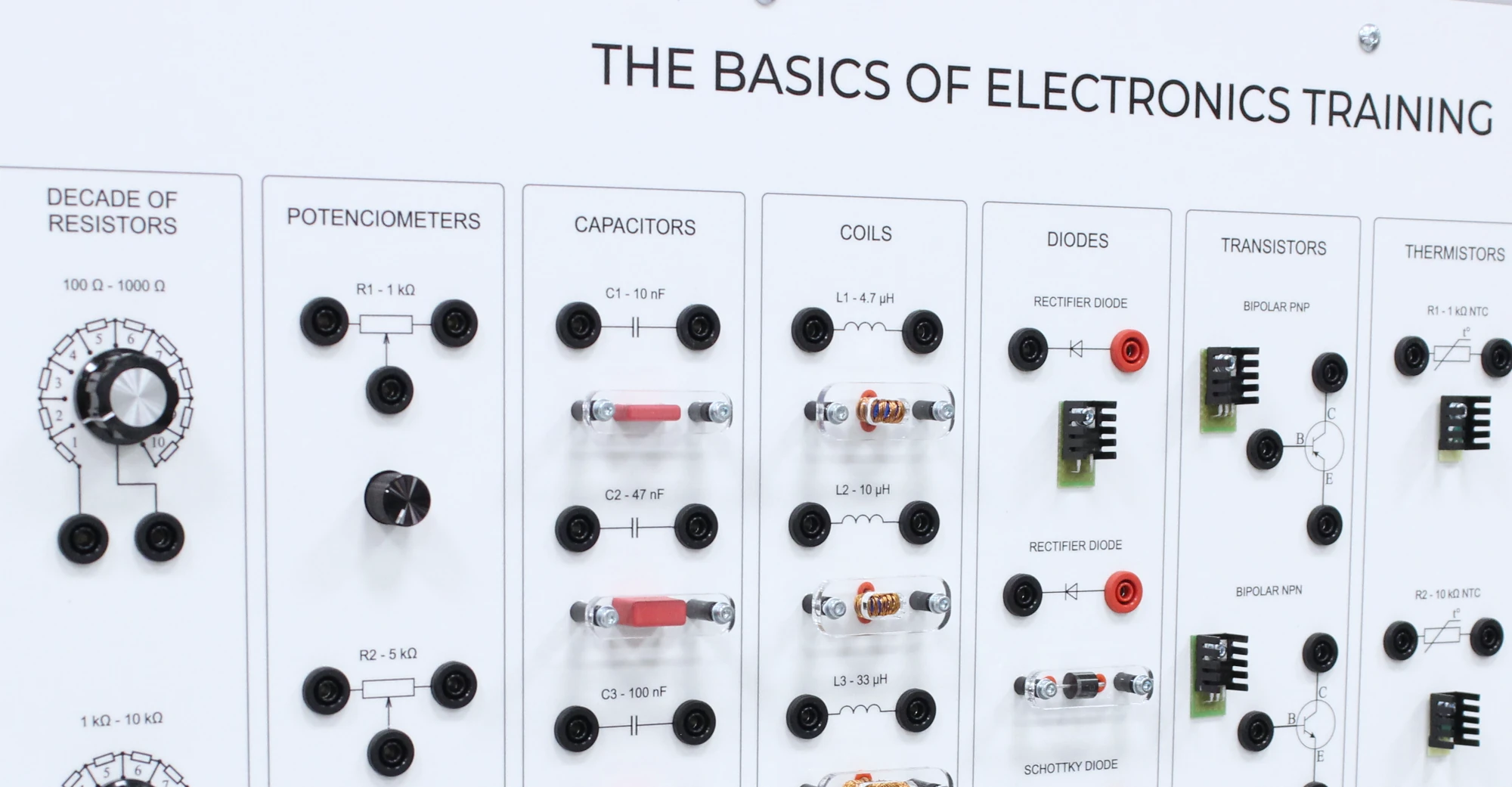

From a service and diagnostic standpoint, cylinder deactivation adds a layer of complexity to engine design. That’s why at AutoEDU, we emphasize practical training on these systems. Students learn how to:

-

Identify when a cylinder deactivation system is active using scan tools and live data.

-

Test oil control solenoids and hydraulic circuits that manage the valvetrain.

-

Analyze customer complaints related to rough idle, ticking noises, or transition issues.

-

Interpret fault codes and confirm whether cylinder misfire events are linked to deactivation hardware.

We also teach how to verify deactivation operation using oscilloscope patterns, fuel trim data, and valve motion tests when available.

Summary Table: Cylinder Deactivation at a Glance

| Mode |

Deactivated |

Active |

| Fuel Use |

Reduced fuel consumption |

Full fuel injection |

| Emissions Output |

Lower CO₂, NOₓ output |

Standard emissions |

| Engine Load |

Lower friction, reduced pumping loss |

Full power and torque delivery |

| Sound/Vibration |

Slightly quieter operation |

Normal engine sound and response |

| Maintenance Focus |

Oil pressure & valve control devices |

Standard ignition and fueling systems |

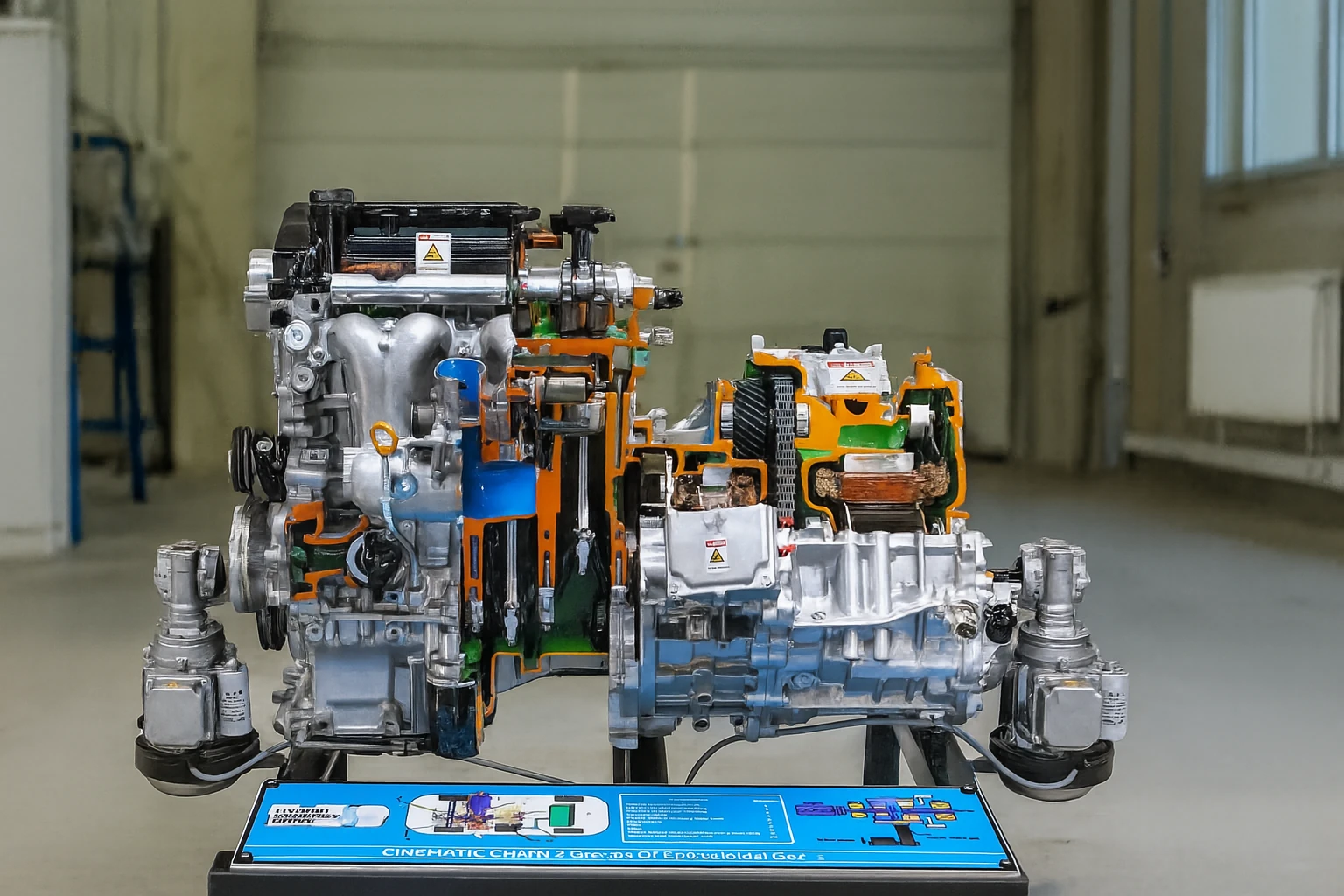

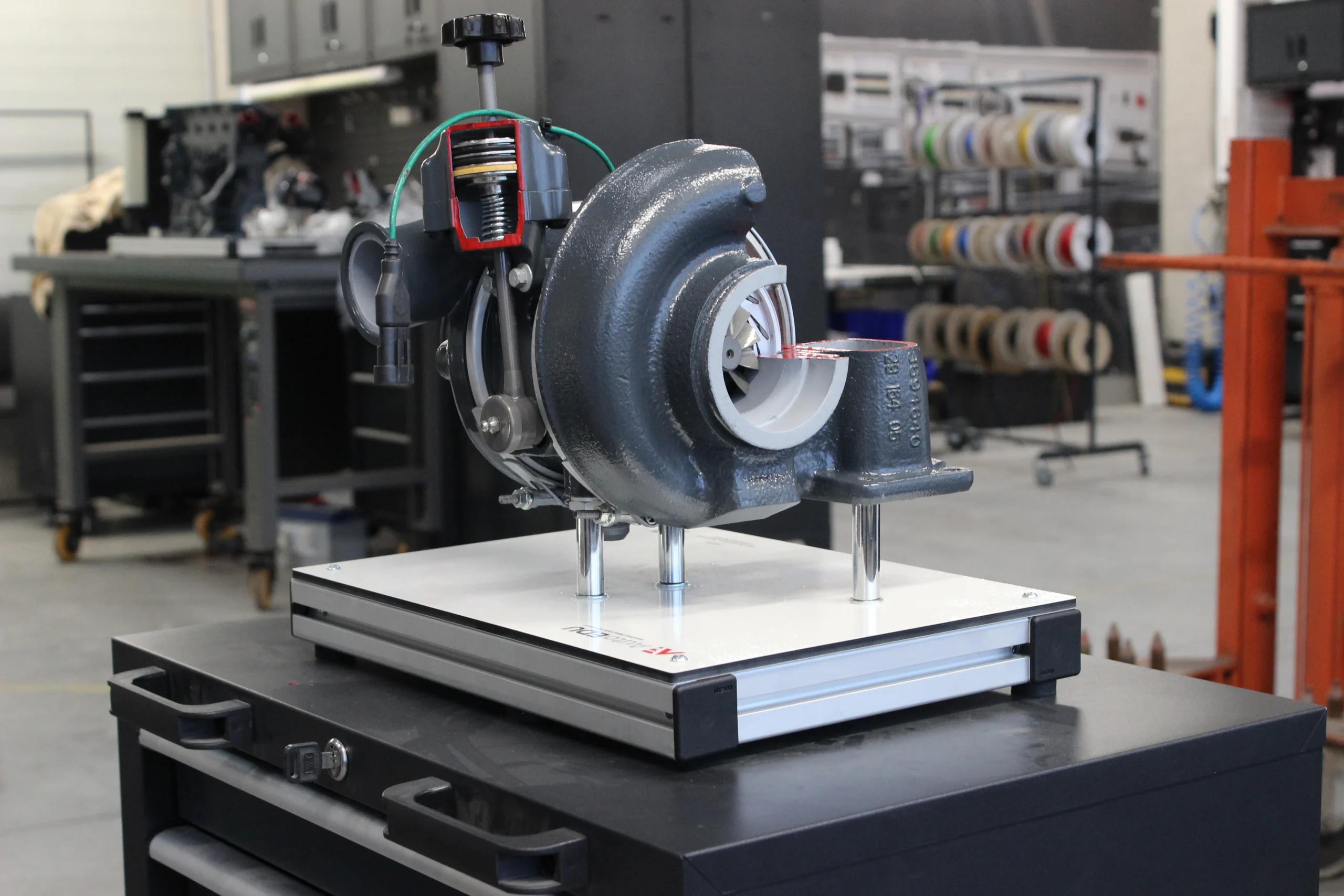

Related AutoEDU Products for Cylinder Deactivation Training

Looking to teach or learn more about this system hands-on? AutoEDU offers complete training platforms that simulate real cylinder deactivation in modern engines.

You can find related products here!

Cylinder deactivation isn’t just a clever trick—it’s an important solution in today’s balance of performance, economy, and emissions. It brings together old-school mechanical knowledge and modern control systems. For future technicians, understanding how this system works—and how to service it—is a must.

AutoEDU’s training systems help bridge the gap between theory and hands-on experience, making sure students can explain, diagnose, and work with these systems in any shop.

Want a visual diagram or classroom handout version of this post? Just let us know—we’re here to support your learning goals.