Real Automotive Training with OEM Equipment

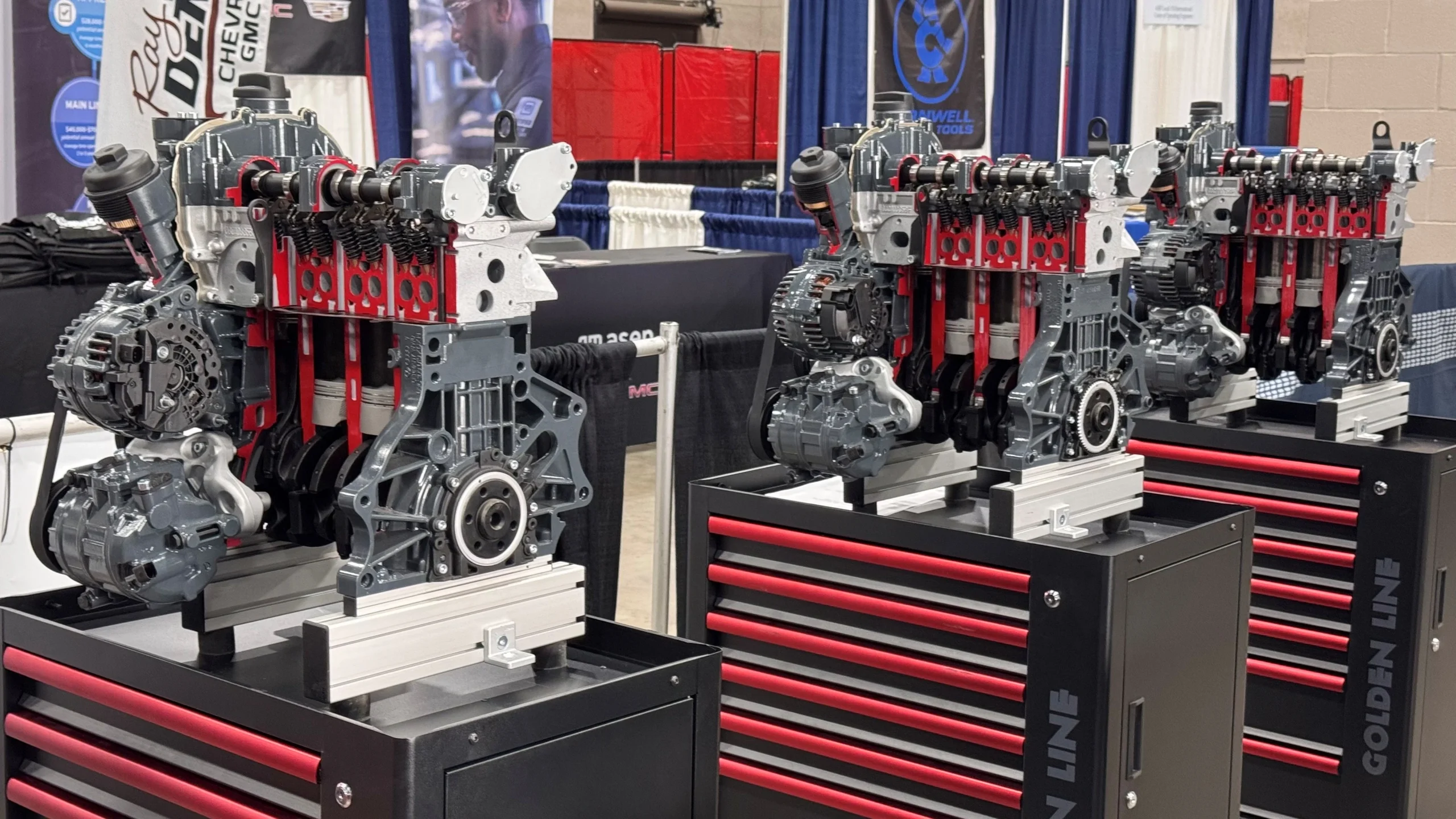

The AutoEDU IVDB03 Petrol (Gasoline) DOHC Engine Cutaway Educational Trainer is designed to teach engine structure, repair procedures, and diagnostics using real parts. Built from actual OEM components, this automotive training equipment gives students real-world experience with internal combustion engines.

This automotive teaching equipment is part of AutoEDU’s “plug-and-train” series. It is compact, safe, and ready to use immediately in classrooms or training centers.

Core Training Features

The IVDB03 trainer supports over 30 practical tasks. It covers key systems and operations, providing full visibility and safe interaction. The following features are taught for engine servicing and diagnostics:

- Engine chain replacement procedures, including guide and tensioner installation.

- Practice loosening the tensioner, removing and replacing the auxiliary belt, and inspecting auxiliary components.

- Auxiliary belt system with tensioner, alternator, cooling pump, and AC compressor.

- Set and check Top Dead Center (TDC).

- Perform camshaft alignment and adjustment with tools.

- Learn auxiliary pulleys, cooling pump, alternator, and AC compressor removing and changing techniques.

- Cross-section view of the engine block, cylinder head, crankshaft, pistons, camshaft, valves, and rocker arms.

- Manual crank rotation to observe piston, valve, and camshaft movement in real time.

- Visible lubrication and cooling system channels.

This structured training covers both visual understanding and practical mechanical skills. It helps students learn how to service engines using correct tools and methods.

Engine Cutaway for Functional Education

The trainer uses a DOHC Petrol (Gasoline) engine, modified for visibility and safety. Key internal parts are sectioned and color-coded. Students rotate the crank manually to see how engine parts move together, helping them understand real-time timing and synchronization.

With the included toolkit, learners perform timing chain replacement, valve checks, and camshaft alignment. Real service tasks like pump replacement and TDC setting are carried out using clear, step-by-step instructions.

Easy Setup and Daily Use

The IVDB03 unit is fully assembled and delivered in ready-to-train condition. Its durable frame and reduced torque values ensure safe repeated use. It fits into any technical classroom with dimensions of 800 × 600 × 1200 mm.

All bolts are adjusted for classroom use with torque settings 3× lower than standard OEM specs, allowing students to work safely without risk of damage.

Instructor Advantages

This automotive training system makes it simple to show complex engine operations. Instructors can demonstrate engine motion, auxiliary drive layout, and timing functions using real components. With video support and tools included, instructors reduce prep time and repeat lessons easily.

Student Learning Outcomes

Students receive full exposure to engine construction and repair. They build confidence by performing real tasks like belt service, chain replacement, and camshaft timing. Working on real OEM parts prepares learners for employment in workshops or service centers.

As part of AutoEDU’s automotive fault diagnosis training equipment, this model helps students apply theory in real-life scenarios.

Tested in Competitions

The IVDB03 was successfully used at SkillsUSA 2025, proving its value in real training competitions. Instructors and students provided strong positive feedback, especially for its clarity and task-based learning structure.

For Modern Automotive Education

AutoEDU IVDB03 is a complete solution for hands-on learning. It serves as an ideal tool in programs using engine trainers, cutaway models, gearbox models, and functional models. As a global automotive training equipment supplier, AutoEDU provides quality tools for real skill development.

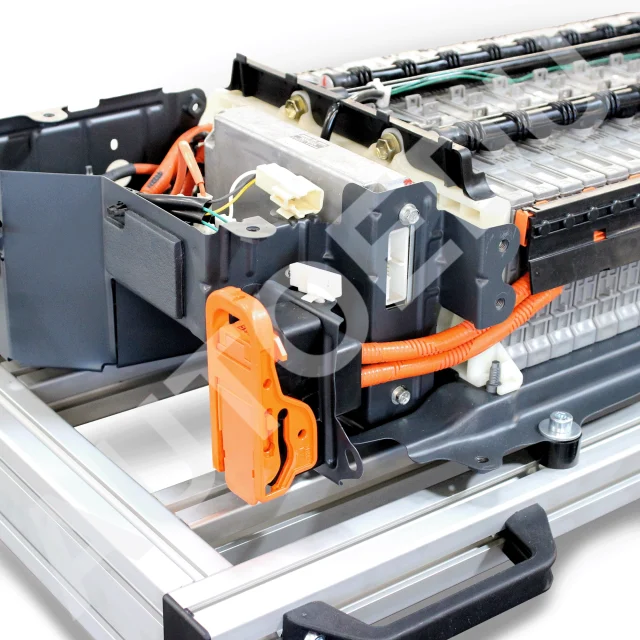

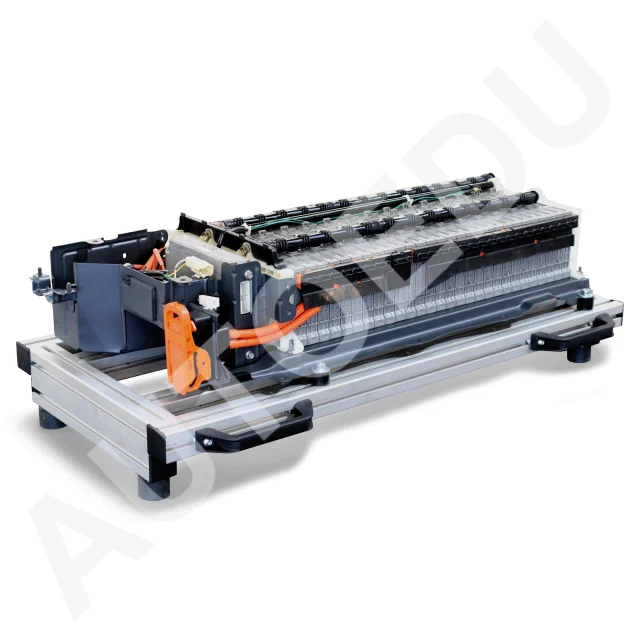

This product supports education in both traditional Petrol (Gasoline) engines and modern systems, including electric car education and hybrid vehicle training.

Why Choose AutoEDU

AutoEDU is one of the top three global experts in automotive training equipment. With over 22 years of experience, we have delivered educational tools to more than 70 countries, completing 500+ projects per year. Our product line includes 400+ functional trainers, all built using real vehicle components.

We help educational institutions train the next generation of automotive professionals by offering practical, effective, and ready-to-use automotive training systems. Our trainers allow students to perform 10 to 50+ tasks per unit under real classroom conditions, aligned with 45-minute sessions and educational program requirements.

AutoEDU is trusted by over 1,000+ training centers worldwide. Our mission is to create custom, reliable, and efficient solutions that improve training quality and meet specific needs. With our experience and fast implementation process, we provide not just equipment—but complete support from project planning to delivery and integration.