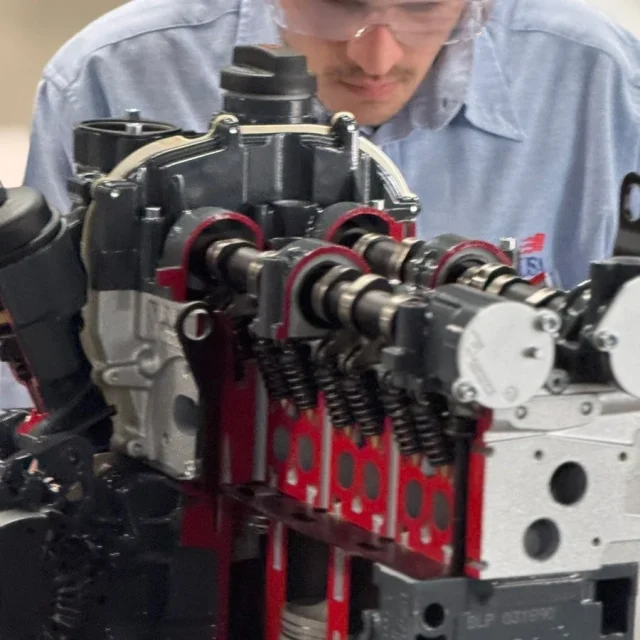

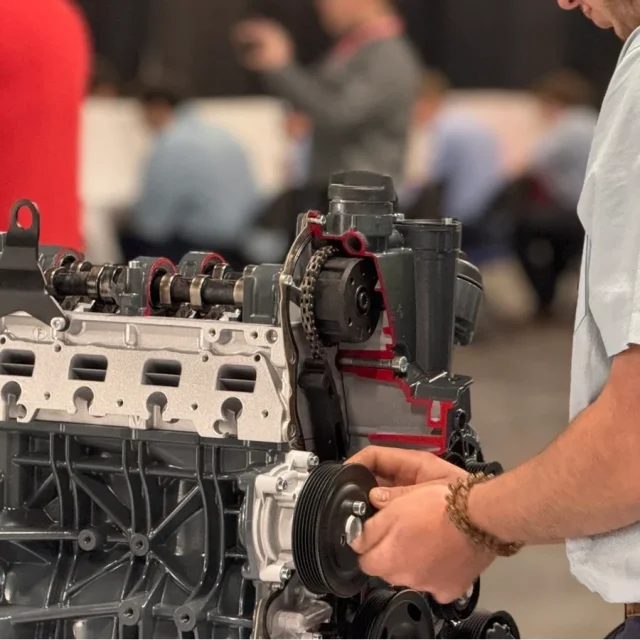

DOHC petrol engine sectioned cutaway.

Visible crankshaft, pistons, connecting rods, camshafts, valves, rocker arms, timing chain, lubrication, cooling system.

Manual crank rotation to observe synchronized movement.

Auxiliary drive system with belt, tensioner, pulleys, alternator, cooling pump, AC compressor.

Supports 30+ practical tasks: belt removal, auxiliary component replacement, timing service, TDC setting, camshaft alignment.

• Understand DOHC engine architecture, component function, lubrication, cooling, and gas exchange systems.

• Learn timing chain layout, tensioner setup, guide installation, and chain replacement.

• Practice auxiliary belt removal, tensioner release, pulley, alternator, cooling pump, and AC compressor service.

• Develop Top Dead Center (TDC) setting, piston-to-valve clearance check, and timing mark alignment.

• Perform camshaft alignment, valve clearance check, rocker arm inspection, and adjust to factory specs.

• Complete over 30 practical tasks, including system inspection, fault simulation, and basic measurements.

• Demonstrate engine kinematics, crank-piston-valve synchronization, and auxiliary system operation.

• Teach auxiliary drive service, chain replacement, TDC setup, camshaft timing, and valve adjustment.

• Provide over 30 practical covering inspection, replacement, alignment, torque procedures, and functional checks.

• Use included tools, technical data, guides for efficient and repeatable classroom sessions.

The trainer supports over 30 practical tasks for technical training.

Example tasks with available video instructions:

This trainer was showcased at the SkillsUSA 2025 events, where it was featured in live demonstrations and practical challenges.

Its proven performance in real training environments is supported by positive feedback from instructors, students, and event organizers.