At AutoEDU, we’re all about understanding automotive systems through hands‑on learning. In this post, you’ll see how turbochargers and superchargers deliver more horsepower—and how to think like a technician evaluating performance upgrades.

What Is Forced Induction?

Both turbochargers and superchargers are types of forced induction systems—they boost engine power by compressing extra air into the cylinders before combustion. This allows more fuel to burn and delivers more horsepower per engine blast.

Superchargers: Instant Boost from the Crankshaft

A supercharger is mechanically driven—usually by a belt connected to the engine’s crankshaft or sometimes by an electric motor. As the engine runs, it spins the compressor and forces extra air into the intake manifold.

Pros:

-

Immediate throttle response with no lag.

-

Strong low-end torque—ideal for racing or performance driving.

-

Simple to install and reliable.

Cons:

-

It uses some engine power to drive the compressor.

-

Lower fuel efficiency since energy is used to power itself.

-

Belt and mechanical components require regular maintenance.

Turbochargers: Power from Exhaust Waste

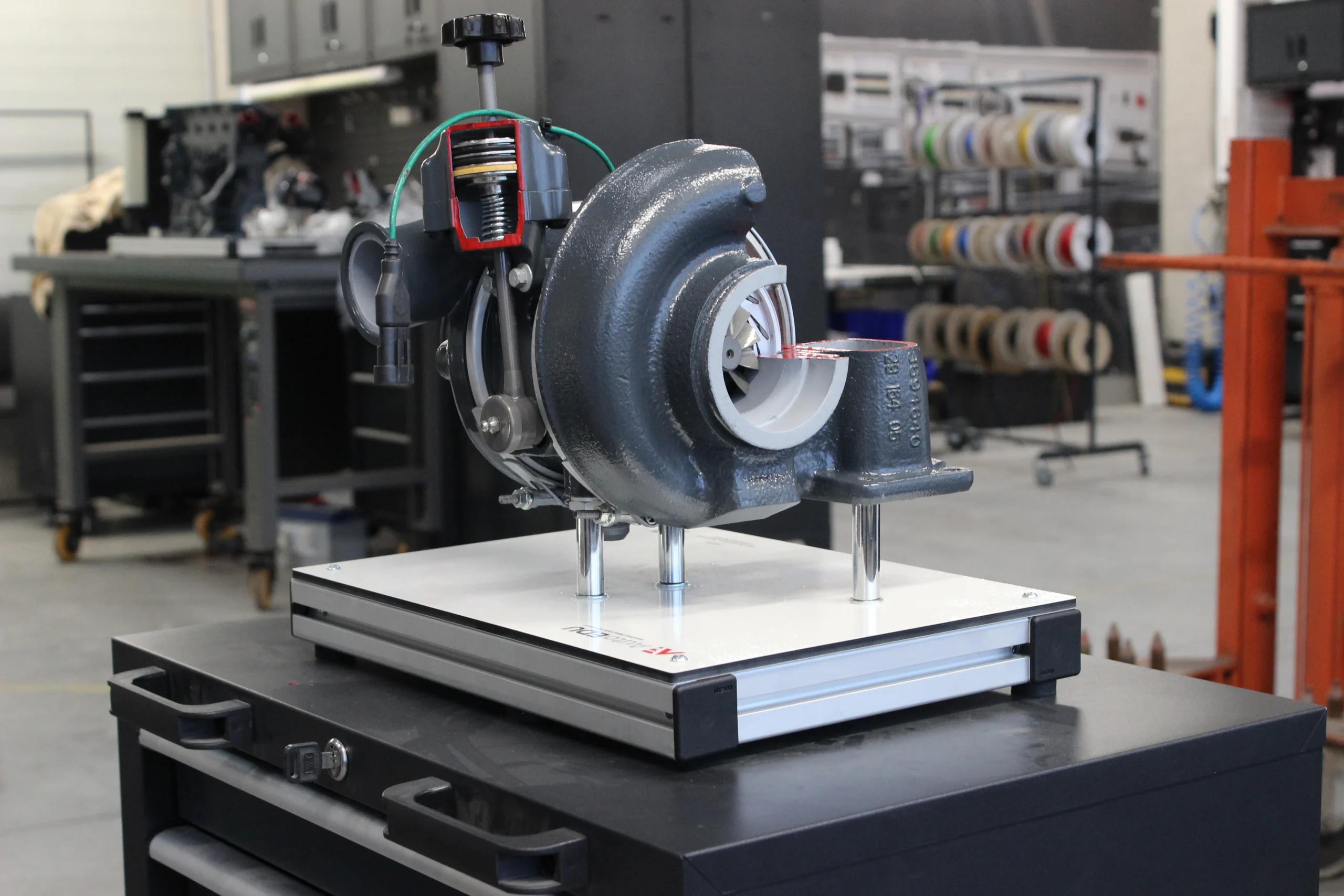

A turbocharger uses energy from hot exhaust gases to spin a turbine that drives a compressor. That compressor pressurizes intake air and pushes it into the engine for more power.

Pros:

-

Uses “wasted” exhaust energy, so it boosts efficiency.

-

Allows smaller engines to produce big power—great for downsizing.

-

Better fuel economy under light use.

Cons:

-

Turbo lag: delay before boost kicks in at higher RPM.

-

More complex installation—requires oil lines, intercoolers, and tuning.

-

Produces heat and needs strong cooling and lubrication systems.

A Bit of History

The roots of forced induction date back to the 19th century. Early superchargers were based on air pumps used in industrial applications, such as the Roots blower patented in the 1860s. The first use of a mechanically driven compressor on an internal combustion engine came in the early 20th century, and by the 1920s, Mercedes-Benz was producing cars labeled “Kompressor” with supercharged engines for added power.

Turbocharging was pioneered by Alfred Büchi, a Swiss engineer, who patented the concept in 1905. He envisioned using exhaust gases to drive a turbine that would compress intake air. Turbochargers became widely used in marine and aircraft engines in the 1920s and 1930s, especially for increasing performance at high altitudes. Passenger cars began to adopt turbocharging more broadly in the 1980s, with manufacturers looking to extract more performance and fuel efficiency from smaller engines.

Choosing Between Turbo and Super

Fuel efficiency and emissions regulations have driven automakers to favor turbochargers, especially in compact, fuel-efficient engines. Turbocharged inline‑4 and inline‑6 engines now replace larger, naturally aspirated V‑6s and V‑8s in many models.

Still, some high-performance vehicles benefit from superchargers’ instant response. Manufacturers like Mercedes-AMG have even introduced electric superchargers paired with turbos to eliminate lag and optimize power delivery across the RPM range.

Real‑World Technician Insights

At AutoEDU, we train students to diagnose and understand forced induction systems, including:

-

Recognizing boost delivery and throttle response differences

-

Inspecting oil and cooling system requirements for turbos

-

Checking belts, drive components, and pulley alignment on superchargers

-

Using dyno or scan tools to evaluate boost pressure and performance

Hands‑on experience with both turbos and superchargers gives students the confidence to understand why certain systems are used—and how to maintain and troubleshoot them effectively.

Summary Table

| Feature | Turbocharger | Supercharger |

|---|---|---|

| Source of boost | Exhaust gas turbine | Belt/electric motor driven |

| Boost response | Delayed (lag at low RPM) | Instant, no lag |

| Efficiency | High (uses waste energy) | Lower (draws engine power) |

| Installation | Complex — needs oil/cooling lines | Simpler, bolt‑on style |

| Maintenance impact | Requires cooling/oil checks | Mechanical/belt system upkeep |

Understanding forced induction isn’t just about recognizing a turbo or a supercharger. It’s about knowing how and why engineers choose one over the other—balancing performance, response, efficiency, and cost.

At AutoEDU, our training helps students explore both systems hands-on, preparing them to handle diagnostics and performance analysis in real-world vehicles. Whether boosting efficiency or chasing horsepower, knowing the “how” and “why” makes all the difference.

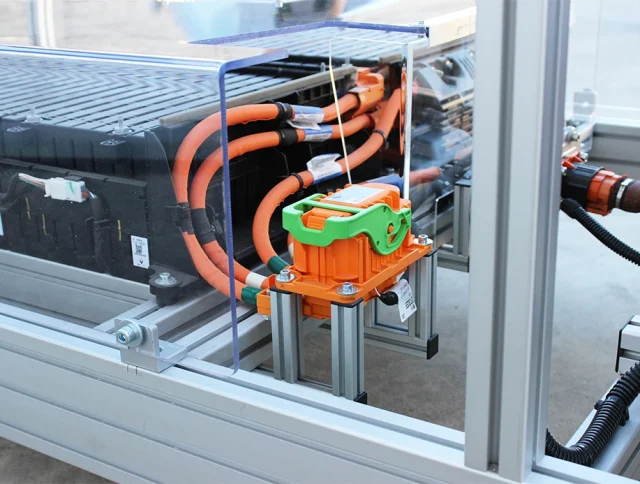

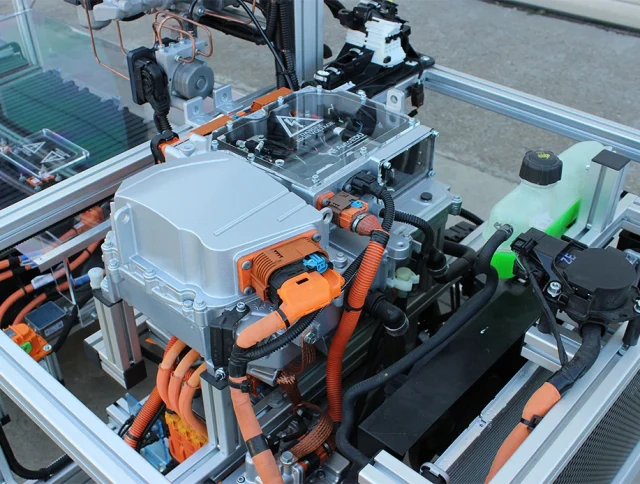

The MSEV03 Electric Vehicle Educational Training Stand is set to revolutionize automotive education, providing students and teachers with an unparalleled learning tool that bridges the gap between theoretical knowledge and practical application.

The MSEV03 Electric Vehicle Educational Training Stand is set to revolutionize automotive education, providing students and teachers with an unparalleled learning tool that bridges the gap between theoretical knowledge and practical application.